Styrofoam: Uses, Properties, and Environmental Concerns

Chính Sách Vận Chuyển Và Đổi Trả Hàng

Miễn phí vận chuyển mọi đơn hàng từ 500K

- Phí ship mặc trong nước 50K

- Thời gian nhận hàng 2-3 ngày trong tuần

- Giao hàng hỏa tốc trong 24h

- Hoàn trả hàng trong 30 ngày nếu không hài lòng

Mô tả sản phẩm

Styrofoam, often referred to generically as expanded polystyrene (EPS), is a lightweight, versatile material with numerous applications. It's known for its insulating properties and shock-absorbing capabilities, but its environmental impact is a growing concern. This comprehensive guide explores the uses, properties, and environmental considerations surrounding styrofoam.

Understanding Styrofoam: Properties and Production

Physical Properties and Characteristics

Styrofoam's distinctive properties stem from its chemical structure. It's produced by injecting expanding agents, typically pentane, into polystyrene beads. These beads are then heated, causing them to expand and fuse together, forming a rigid, low-density foam. The resulting material is characterized by its excellent insulation, buoyancy, and resistance to moisture and chemicals. Its lightweight nature makes it easy to handle and transport, contributing to its widespread use in various industries. The closed-cell structure minimizes water absorption, making it ideal for applications involving liquids or humidity.Manufacturing Process

The manufacturing process of styrofoam is relatively straightforward, involving several key steps. First, polystyrene beads are manufactured through a polymerization process. These beads are then combined with a blowing agent, typically pentane, which expands the beads when heated. This expansion process is carefully controlled to create a uniform foam structure. The expanded beads are then molded into the desired shape using steam or heat. Finally, the molded product is allowed to cool and harden, resulting in the familiar rigid styrofoam product.Common Applications of Styrofoam

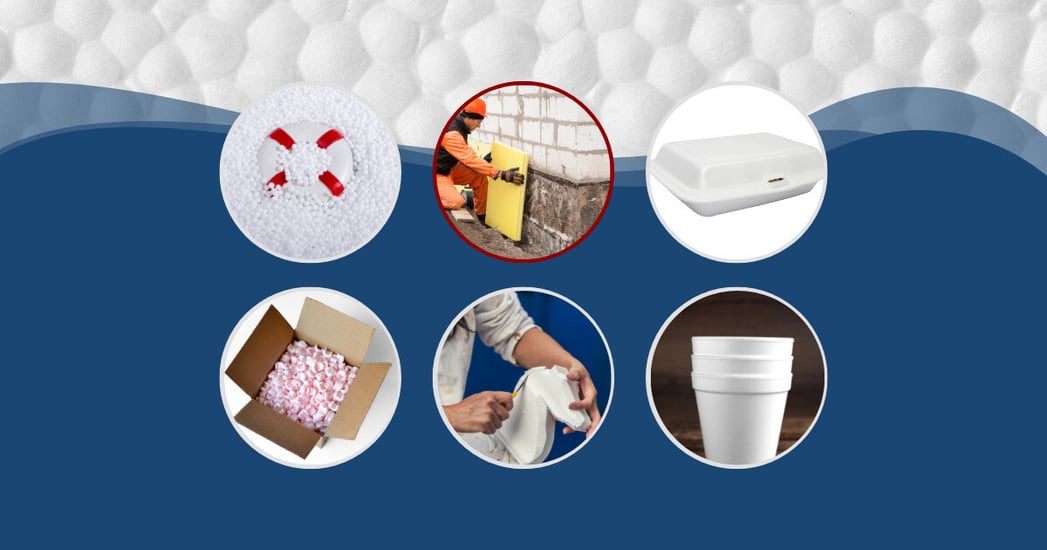

Packaging and Protection

Styrofoam's shock-absorbing properties make it an excellent material for packaging fragile items. From electronics to glassware, styrofoam provides a protective barrier during shipping and handling. Its lightweight nature also reduces shipping costs, further enhancing its economic appeal in this context. The ease of molding it into custom shapes allows for precise protection of irregularly shaped items.Insulation

The excellent insulating properties of styrofoam make it a widely used material in construction and refrigeration. In buildings, styrofoam insulation helps maintain consistent temperatures, reducing energy consumption and costs. In refrigeration applications, it keeps perishable goods cold, minimizing spoilage and waste. Its resistance to moisture also makes it suitable for applications in humid environments.Other Uses

Beyond packaging and insulation, styrofoam finds applications in various other industries. It is used in the creation of disposable tableware, buoys, and even as a component in certain types of art and craft projects. The versatility of the material allows for customization and adaptation to diverse needs. However, the environmental impact of these uses is increasingly scrutinized.Environmental Concerns and Sustainability

Non-Biodegradability and Waste Management

One of the significant drawbacks of styrofoam is its non-biodegradability. It persists in the environment for hundreds, even thousands, of years, contributing to landfill waste and pollution. This poses a serious environmental challenge, particularly given the widespread use of the material. Proper waste management strategies, including recycling and responsible disposal, are crucial to mitigating the impact. However, the recycling infrastructure for styrofoam is not as widely developed as for other materials.Impact on Wildlife and Ecosystems

The persistence of styrofoam in the environment poses significant risks to wildlife and ecosystems. Animals may ingest styrofoam pieces, mistaking them for food, leading to internal injuries or blockages. Furthermore, styrofoam can break down into smaller microplastics that contaminate water bodies and soil. These microplastics pose a threat to aquatic life and can enter the food chain, potentially affecting human health as well. The impact on biodiversity and ecosystem stability is a growing concern.Recycling and Alternatives

While styrofoam recycling is not as common as some other plastics, there are efforts to develop more efficient recycling processes and solutions. The challenges often lie in separating styrofoam from other materials and the energy required in the recycling process. However, some companies are actively developing innovative recycling technologies to overcome these challenges. Furthermore, the search for sustainable alternatives is gaining momentum. Biodegradable and compostable materials are increasingly being explored as replacements for styrofoam in various applications.Reducing Styrofoam Consumption: Individual and Collective Actions

Reducing styrofoam consumption requires a multi-pronged approach, involving both individual and collective actions. Consumers can make conscious choices to reduce their reliance on styrofoam products, opting for reusable alternatives whenever possible. Businesses can adopt sustainable packaging practices, exploring biodegradable alternatives and minimizing their styrofoam footprint. Policymakers have a crucial role to play in implementing regulations to incentivize the development and adoption of sustainable alternatives, while improving recycling infrastructure and addressing the challenges related to waste management of styrofoam. In conclusion, styrofoam is a versatile material with numerous benefits, but its environmental impact cannot be ignored. A balanced approach that weighs the material's utility against its negative consequences is essential. The focus should be on reducing consumption, improving recycling infrastructure, and promoting the development and adoption of sustainable alternatives to mitigate the long-term environmental effects of styrofoam.Sản phẩm hữu ích: sự tích hoa tỉ muội trắc nghiệm

Sản phẩm hữu ích: tắm nắng mấy giờ là tốt

Sản phẩm liên quan: thơ về lòng yêu nước

Sản phẩm hữu ích: tiểu thuyết về cuộc sống